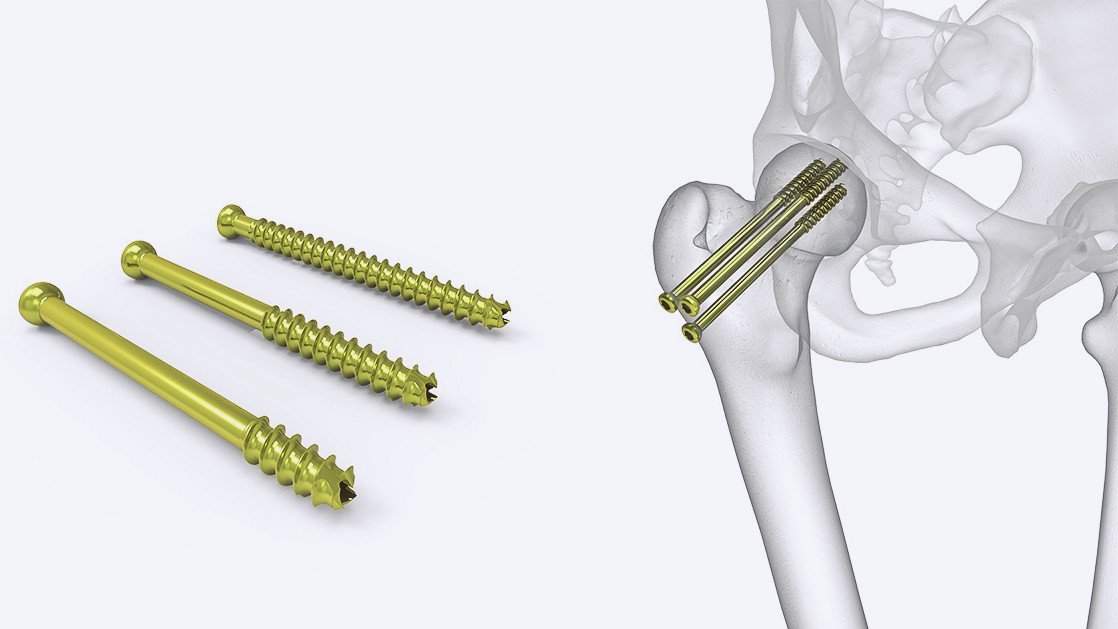

Cannulated Screw

The use of cannulated screw is the precise insertion in epiphyseal or metaphyseal site over a guide wire. This reduces the problem of having to remove and reposition an incorrectly placed screw. A guide wire correctly visualizes the path of the screw. Moreover, the guide wire maintains the reduction as well as controls the fracture fragments. If position of guide wire must be changed, it may be done without enlarging the hole and sacrificing bone’s purchase strength. Final placement of the screw needs use of cannulated drill as well as occasional use of a cannulated tap. The screwdriver is cannulated too. Cancellous cannulated screws come in small and large sizes.

Large cannulated cancellous screws are utilized to fix fractures of the femoral neck, tibial plateau and femoral condyle. The use of small cannulated cancellous screws is for fixation of the distal-radius, distal-humerus, carpal scaphoid, distal and proximal tibia. In comparison with an equivalent non-cannulated screw, the greater root diameter required to accommodate the central bore of the cannulated screw efficiently reduces holding power to some extent.

The cannulated screw head has either an inner hexagonal recess to work with a cannulated screwdriver, or an associate external hexagonal or square head as well as a cannulated wrench. The internal recess design enables use of a slim screwdriver and allows a spherical outer shape to the screw head. This may be important in removal of screw. Bone growing around a head of screw with an external hexagonal head makes removal hard. Since, it is also important to remove bone enable engagement of the wrench. If 2 external hexagonal screw heads touch, they will lock.

The benefit of using the external hexagonal head is the strength offered to the coupling with the driving wrench. The round head with an internal recess puts more demand on the tip of screwdriver. The screwdriver’s hexagonal tip must be small sufficient to fit within the recess in the screw head, yet itself must be cannulated, leaving slight material in it. Moreover, strength of the screw head-shaft junction is essential. The internal hexagonal recess removes head material. If this recess is very deep, the head-shaft junction may lose the strength.

To maintain strength, the design of the shaft’s diameter of a cannulated screw is usually slightly larger than that of a solid screw of size that is comparable. Since the cylinder’s stiffness in bending is a function of the third power of its radius, a small rise in the shaft’s outer radius will compensate for the cannula. Cannulation doesn’t appear to be a problem in the greater screws, but in a smaller screw leaving a cannulation big enough for stiff guide wire can require the shaft diameter to be significantly increased or the screw will be significantly weaker. There is a misapprehension that a solid screw is stronger than a cannulated screw of an equal outer thread diameter.

The 6.5 mm cannulated screw often has a little larger shaft (root) diameter than its solid 6.5 mm counterpart. A solid 6.5 mm can have a 3.0 mm thread root diameter. While on the other hand, 6.5 mm counterpart has a root diameter of 4.8 mm. If the cannula is 2 mm in diameter, the area as well as polar moments of inertia of the cannulated screw would be 102.6 mm and 514.8 mm in comparison with 27 mm and 81 mm, i.e. 3.8 and 6.4 times larger, respectively, than those of the solid screw. A cannulated screw must have a bigger root diameter than the solid screw to enable room for the cannula. This does reduce its holding power, as the thread depth is smaller. Clinically cannulated screws appear to function fine and have more than enough holding power.

A cannulated screw for cancellous bone should be self-tapping and self-cutting. The screw tip cuts only when turned clockwise and is blunt when rotated counterclockwise (removal direction). A self-cutting, self-tapping tip is beneficial in percutaneous procedures. After positioning the guide pin, the screw advances through the soft tissue while turning in a counterclockwise direction. The tip doesn’t cut or wind the soft tissues. When the cortex reaches, the rotation reverses to clockwise, enabling it to cut into the bone.

The Herbert Screw

The Herbert screw is a specialized orthopedic implant to achieve interfragmentary compression. There is no head in this. Unique device and threads are present at both ends of the bone screw, with a pitch differential between the trailing and leading threads. The intention for the bone screw is to bury under a bony surface. One can attain interfragmentary compression by the difference in thread pitch: the coarser pitch moves the orthopedic screw a greater distance through bone with every turn than does the finer pitch. As the screw twists, the bone surfaces come together creating compression.

Thus, one does not need a screw head. In absence of a screw head it’s possible to insert this bone screw through articular surfaces without the head being prominent. A cannulated version is accessible: Cannulated Herbert screw enables percutaneous scaphoid fracture fixation, avoids prolonged cast immobilization and enables a more rapid return to work or sport.

A cannulated Herbert screw is easier to install than an uncannulated version and provides better protection to the bone spicules that interdigitate between the screw’s threads in comparison with cases in which the bone is originally tapped, the tap is removed, and the bone screw is then installed during a 3rd pass through the bone threads. Placing a guide wire first enables for correct visualization of the path, position, as well as length of the screw. The guide wire also helps in reduction and control of fractured fragments. Current indications include capitellar, fractures of the carpal scaphoid, fractures, radial head fractures, osteochondritis dissecans, osteochondral fractures, and small joint arthrodesis. The Herbert screw may be quite tough to remove.