Fractures are common injuries, however, they can sometimes be serious requiring surgical intervention. When fractures occur, orthopedic surgeons rely on a variety of tools to reduce the fracture and promote healing. Those tools are orthopedic implants and instruments. One of the most important orthopedic implants that surgeons have is orthopedic screws. These specialized screws come in a wide array of designs, each suited for a specific purpose. In this blog, we will dive into the world of orthopedic bone screws, explore their different types, functionalities, and how they contribute to successful bone fixation.

How Orthopedic Screws Look Like?

Before delving into specific types, let’s understand the common features of bone screws. These screws look like traditional screws and have certain parts:

Head

Head provides a grip for the screwdriver during insertion. Common head designs include hexagonal and star-shaped ones. Depending on the head design, the screwdrivers are used.

Shaft

The main body of the screw, is often cylindrical, with threads running along its length. Threads convert rotational force into compression, pushing bone fragments together. The shaft can be fully or partially threaded.

Tip

The pointed end that initiates the creation of a channel within the bone for screw placement. Advanced bone screws have a self-tapping tip which creates its own threads during insertion.

Core

The central part of the screw. It is sometimes hollow, especially in cannulated screws.

Which Factors Differentiates Bone Screws?

Material

Biocompatible metals like stainless steel and titanium are used for screw manufacturing. Hence, they can be differentiated based on the material they are made from.

Thread Design

Thread depth and pitch (distance between threads) influence how the screw interacts with bone density.

Self-Tapping vs. Non-Self Tapping

Self-tapping screws create their own threads in bone, while non-self-tapping requires pre-drilled holes.

What Are the Different Types of Orthopedic Screws?

Now, let’s explore the most common types of orthopedic screws and their applications:

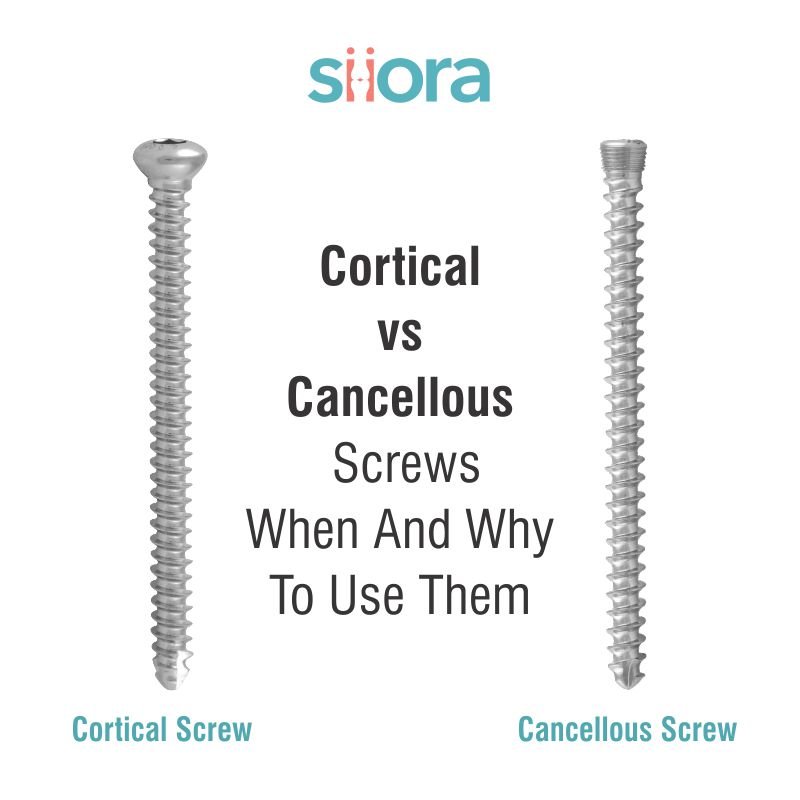

Cortical Orthopedic Screws

Designed for the dense outer layer (cortex) of long bones. They have shallow, closely spaced threads and a blunt tip for stability within the cortex.

Cancellous Screws

Ideal for the spongy inner bone (cancellous bone). These screws have wider threads with deeper spacing to achieve better purchase in less dense bone.

Locking Screws

These innovative screws possess threads along both the shaft and the head. When tightened, the head threads lock against a matching plate, creating a more rigid fixation.

Headless Screws (Herbert Screws)

Completely embedded within the bone, these screws minimize soft tissue irritation and are often used near joints where prominence could hinder movement.

Cannulated Orthopedic Screws

Cannulated screws have a hollow core that allows for the passage of a guidewire during insertion. The guidewire helps ensure accurate screw placement, especially beneficial for complex fractures.

These categories can further be sub-divided based on functionalities:

Lag Screws

Used for compressing bone fragments together. They have a larger diameter at the tip compared to the shaft, creating a lag effect as the screw tightens.

Compression Orthopedic Screws

They are similar to lag screws but with a constant diameter throughout the shaft.

Tension Band Screws

These screws work by converting tension forces across a fracture into compression within the bone.

How Right Orthopedic Screws Are Chosen For Surgery?

The selection of an orthopedic screw depends on several factors, including:

Bone Anatomy

The type of bone (cortical or cancellous) and its size determine the screw diameter, thread design, and length.

Fracture Characteristics

The location, severity, and angulation of the fracture influence the choice of screw type (locking, cannulated, etc.).

Surgical Technique

The surgeon’s preferred approach and the need for additional implants like locking plates may influence screw selection.

Ultimately, the surgeon carefully considers these factors to choose the most appropriate screw for optimal bone healing and functional restoration.

Advancements in Orthopedic Screws to Be Considered

While the core functionalities remain the same, advancements in technology have led to the development of specialized orthopedic bone screws:

Bioabsorbable Screws

Made from bioabsorbable materials like polylactic acid, these screws degrade naturally within the body, eliminating the need for a second surgery for removal. The surgeon considers many factors before deciding to use them during surgery.

Interfragmentary Screws

These tiny screws are used to fix small bone fragments or stabilize specific areas within a fracture.

The future of orthopedic screws likely involves continued refinement of materials and designs to enhance biocompatibility, strength, and minimally invasive surgical techniques.

What About the Removal of Orthopedic Screws?

Following a successful bone healing process after surgery, some patients may require removal of the orthopedic screws. This outpatient procedure is typically performed under local anesthesia. It involves reopening the original incision or creating a new one. The surgeon carefully exposes the screws and removes them using specialized tools.

There may be several reasons that arise for the need for screw removal. This may include discomfort, hardware irritation, infection, or the need for additional procedures. Recovery involves pain management, incision care, and physical therapy to regain strength and mobility. While consulting a doctor is essential to determine if screw removal is necessary and discuss the potential risks and benefits of doing so.

The Last Say

Orthopedic screws play a vital role in modern fracture care. By understanding the different types and their applications, we enhance our knowledge of the intricate world of orthopedic surgery. However, despite the advancements, the orthopedic surgeon chooses the right type of orthopedic screws for different patients after considering different parameters. This is very important to avoid post-surgical complications and ensure proper fracture healing.

A Renowned Orthopedic Screw Manufacturer in India

Siora Surgicals Pvt. Ltd. is an experienced manufacturer of a CE-certified range of orthopedic implants including orthopedic bone screws. Being in this industry for over 30 years, the company has established a good reputation in the global orthopedic market. Siora manufactures all implants in its state-of-the-art manufacturing facility and tests them against stringent quality parameters before sending them to the inventory. The company manufactures different types of trauma implants that fall under 20+ categories. It is also looking to establish its position as a trustworthy supplier of Orthopedic implants in USA. Moreover, Siora has also established its position as a trustworthy OEM service provider in the world.